So a little before leaving for Russia I had to go pick up my dad since the XR 400 had died on him.

Since there was no compression the engine needed to come out, took plenty of pictures to be able to get it back together, especially on the electrical connectors and cable routing:

And it was strange that a small amount of clear oil came out of the oil tank:

But quite a lot of really black oil came out of the engine itself:

Everything went smooth with getting the engine out until I ran into this bolt for the front mount, the frame have a small damage making it impossible to get the bolt out but was possible to get in there with the rotary tool and remove some and it came right out:

Even if Im taking plenty of pictures I take the time to label parts so it will be easy to put together since it will months before assembly (no real hurry won’t aim to do any winter riding this season).

And there it is, an engine on a bench:

Some bracket to make a simple engine stand:

Some cardboard to keep track of every bolt:

Seems to have had oil up by the cam shaft at least:

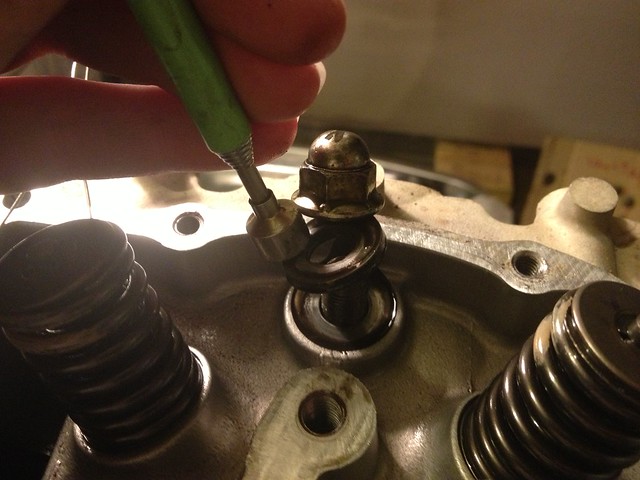

Tensioner out:

Keep track of the dowel pins and there was some other pin also with a small spring under it, pieces that are easy to loose when taking an engine apart:

Head nuts and washers removed:

Not looking good at all:

And with the cylinder of the extent of the damage can be seen:

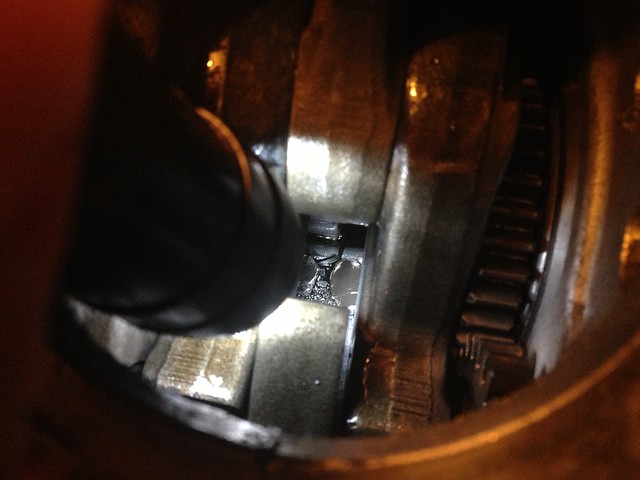

Plenty of pieces down in the crankcase:

Lots of molten aluminum in the bore:

The piston clips needed a lot of force to get out and deformed, will be plenty of new parts before assembling, piston pin needed hammering to get it out:

Cleaning up bore, scraped away with a knife:

Acid was then added to dissolve the last of the aluminum:

And some deep damage from the edge of the busted piston ring:

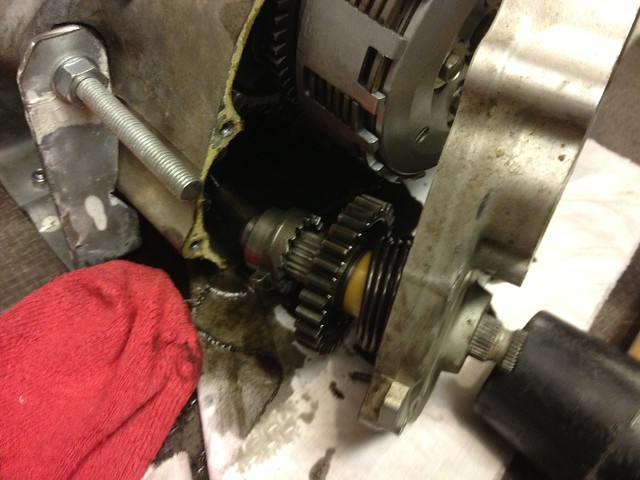

With the amount of pieces down in the crankcase a split will be required, right engine cover coming undone:

All axels with splines seems to be in a way that you can’t put it together wrong at least:

Internal mesh filter seems clear so that was not the cause of bad circulation of the oil:

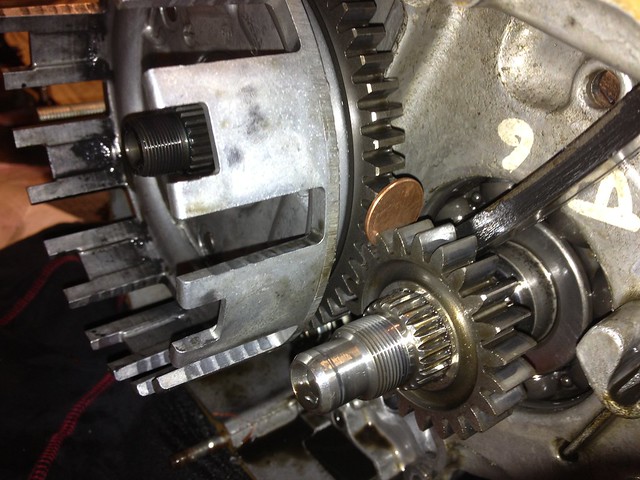

Can be hard to lock an engine to remove clutch basket nut but here is one way:

Clutch removed:

A flywheel puller is needed, seems to be a M20x1,5 bolt will do the trick:

Lucky for me its the same on the KTM 950 Adventure so I had one:

Put clutch basket back in place and used a penny to lock the engine for this:

Flywheel off, keep track of the woodruff key:

Measuring the bore it seem to be stock bore so should be possible to buy an oversized piston to get it running again:

Drilled some holes in the wood to get the engine laying flat for the split:

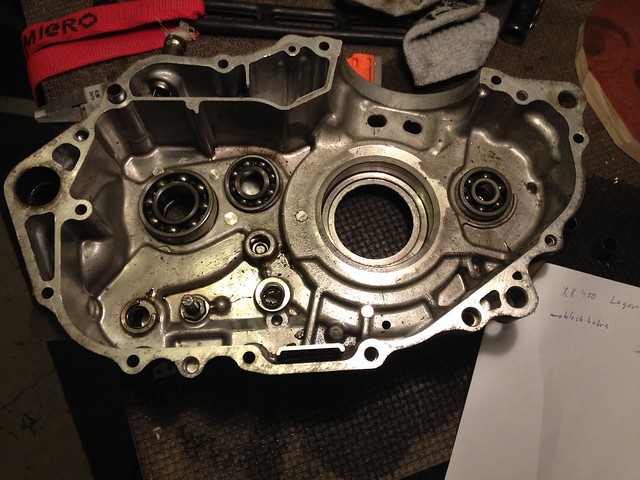

Gearbox exposed:

With the gear box lifted out a little hammering needed to get the crankshaft out (was a little premature, had to put it back to do some measuring later):

Toasted intake valve, new are ordered:

Exhaust valve, might be reused but tempted to buy new all the way around:

Doing some measuring on the crank and the shaft does seem straight so will reuse that:

Bought a blind bearing puller kit that worked great:

The gasket kit I tried ordering from China for very little money have arrived and looks OK, hopefully it will hold up once the bike is back together also:

But the bearing puller for the bearing on the crankshaft does not seem to work that well, will try with some longer threaded rods:

Most bearings out:

Have ordered a few parts already but will replace all bearings and seals so will need to order some more stuff and have the cylinder handed to a mechanics shop to be bored before assembly.

Leave a Reply